Thermal Ceramics Superwool Plus

Superwool plus vf is a vacuum formed insulating product made from a mixture of superwool plus fibres refractory constituents and organic binders.

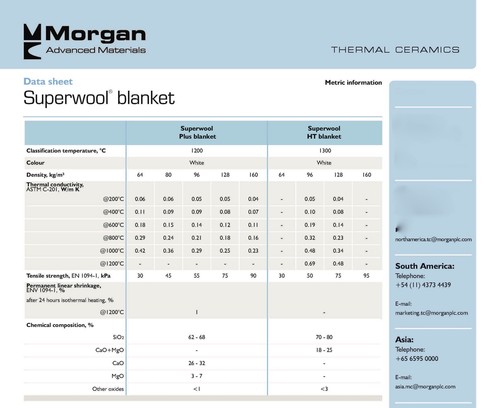

Thermal ceramics superwool plus. The company strategically decided to invest in this new technology on a global basis to allow them to introduce this high performance insulation to a wide range of users. Materials thermal ceramics. We manufacture insulating products including fibre insulating firebrick monolithics microporous and heatshields. Superwool plus offers the same benefits as the other members of the superwool family but with improved handling strength and enhanced thermal properties.

Silicon oxide materi al n otes. Superwool plus is manufactured from pure raw materials using a new manufacturing technology. Thermal ceramics manufactures and installs a wide range of thermal insulation products such as cerablanket kaowool low biopersistent superwool and porextherm microporous products. Lynn manufacturing 1 thick cerablanket insulation.

April 1 2009 as part of a multi national capital project thermal ceramics facility in augusta ga facility is now manufacturing superwool plus. Lynn manufacturing 1 4 thick superwool plus paper morgan thermal ceramics 2000f rated 24 wide 62 5 ft. Superwool plus and superwool ht products are covered by patent numbers. Thermal ceramics superwool.

In addition to enhanced thermal properties large nuisance dust. Superwool is designed from pure raw materials and specially processed to offer excellent performance in high temperature applications. The superwool fibre family of products offer a versatile alternative to traditional insulation solutions for commercial industrial and transportation applications. Lynn manufacturing 1 16 thick superwool plus paper morgan thermal ceramics 2000f rated 24 wide 250 ft.

Superwool offers an alternative to traditional solutions due to its exceptional. Thermal ceramics superwool 607 blanket c ategori es. Only 11 left in stock order soon. The thermal ceramics business of morgan advanced materials offers superwool plus and superwool ht pyro bloc modules as an alternative to traditional solutions due to their unique high refractoriness and excellent non wetting properties for furnace applications requiring direct contact with molten aluminium.

Superwool fibre has been developed to show improved high temperature characteristics required to act as an alternative to rcf where possible. Vacuum forming allows the production of a variety of configurations tailored to the particular application and ranging from simple sections such as tubes cones and flat shapes to complex shapes such as combustion chambers.