Thermal Conductivity Of Cordierite Ceramic

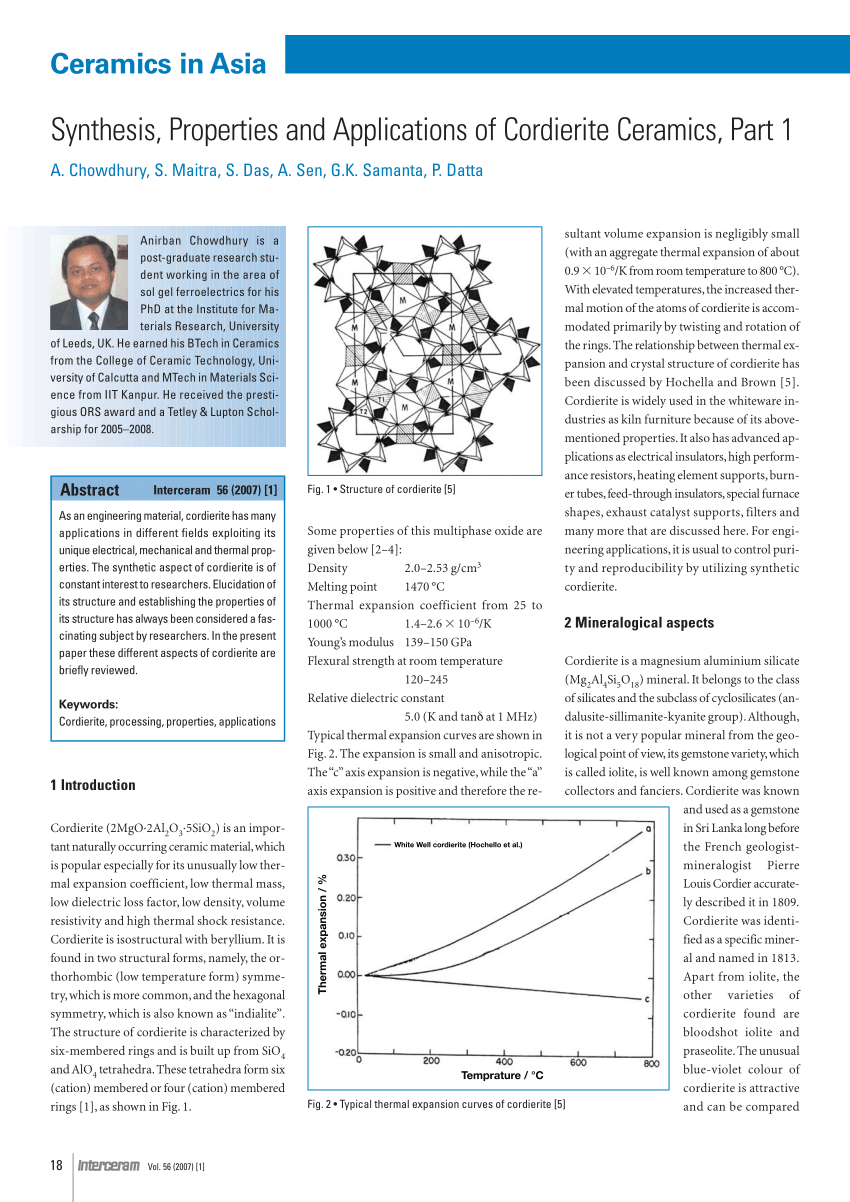

Its low thermal expansion and thermal conductivity make it a good choice for fixtures and other applications.

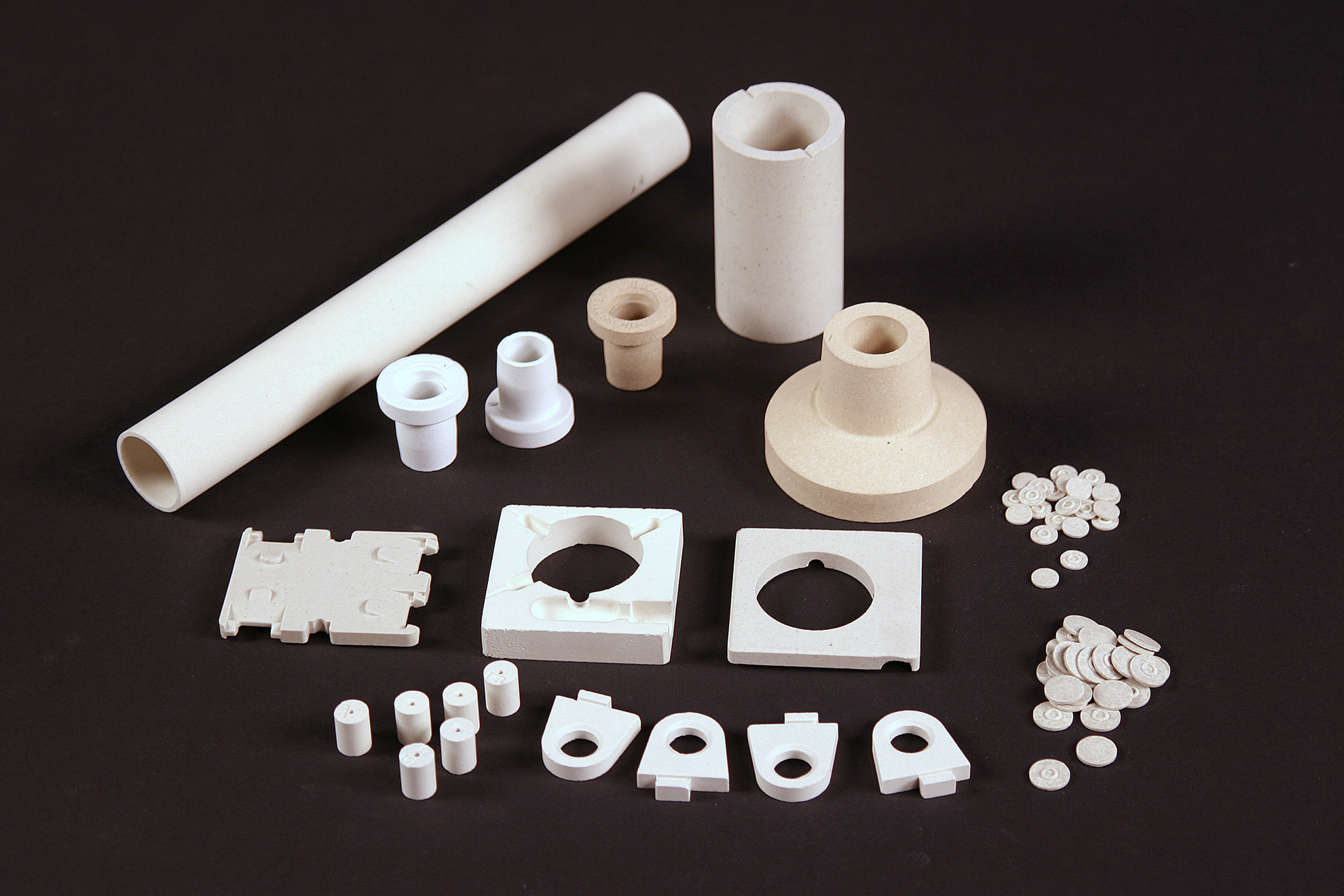

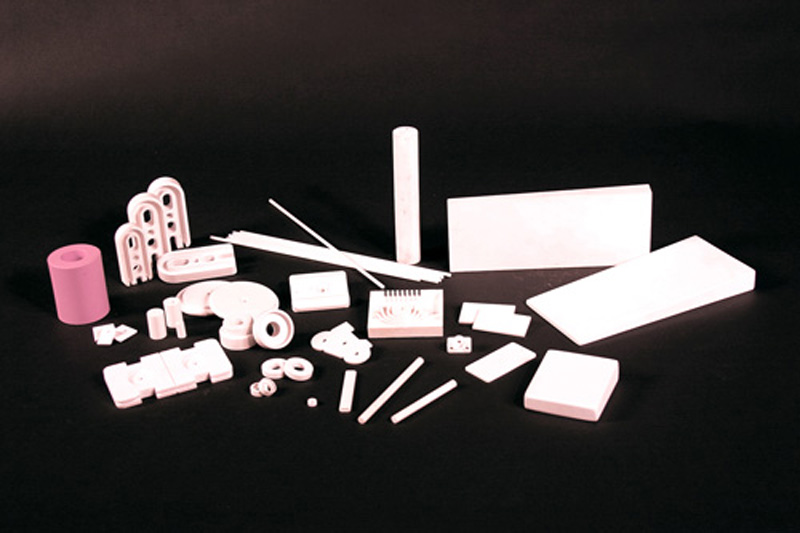

Thermal conductivity of cordierite ceramic. Regarding their capacity to conduct heat silicate ceramic materials i e. Applications include refractory shapes welding tapes heaters. Cordierite ceramic refractory grade unfired cordierite. Its good thermal shock properties lend this material to be used in refractory applications.

Cordierite is used when thermal shock is a concern in the finished product. The content of gum arabic had a great influence on the foaming capacity and the stability of the wet slurry foam. The thermal conductivity of ceramic is generally lower than that of metals such as copper or steel. It is an excellent fit for inexpensive insulators used in manufacturing and durable goods.

Porous ceramic cordierite porosity thermal conductivity sintering degree the highly porous cordierite ceramics were fabricated combining the merits of direct foaming and gelcasting method. Machines over 15 different materials cordierite cordierite properties cordierite is mainly a structural ceramic often used for kiln furniture due to its extremely good thermal shock. Its low thermal expansion and thermal conductivity make it. Cordierite is available in self glazing form where higher strength thermal shock and dielectric strength is required.

Cordierite combines great thermal shock properties low thermal expansion rate and good electrical insulation. Steatite as well as superpyrostat cordierite and forsterite exhibit consistent low values on the same level. Cordierite ceramic is a type of magnesium aluminum silicate with particularly good thermal shock properties. Cordierite also has low thermal conductivity and thermal expansion while also being cost effective.

Cordierite is a magnesium aluminum silicate which possesses an extremely low thermal expansion and low thermal conductivity.