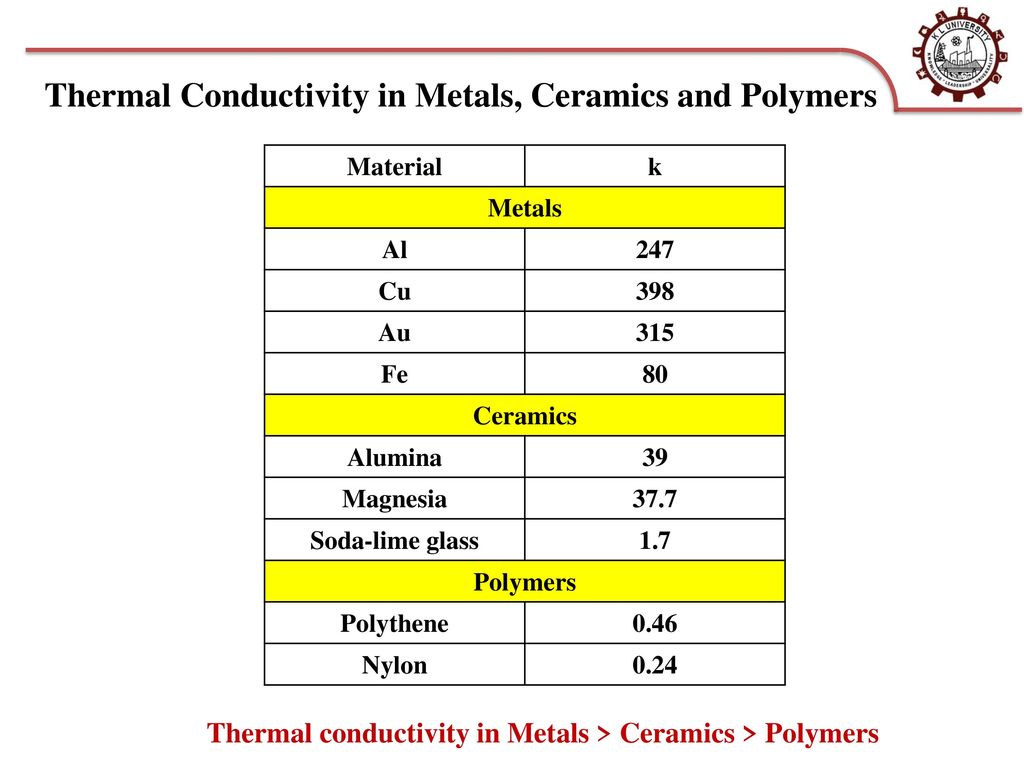

Thermal Conductivity Of Metals Ceramics And Polymers

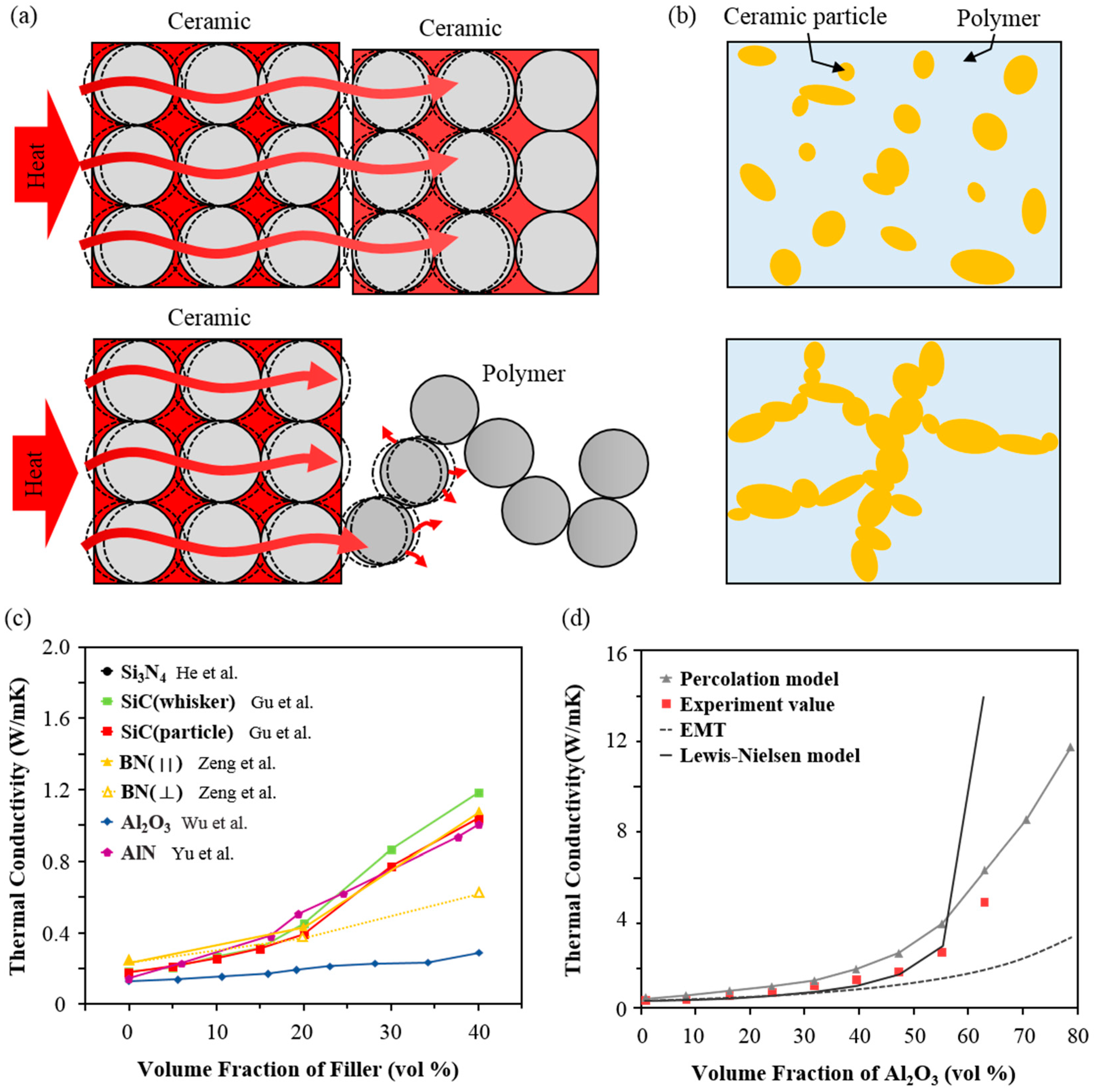

However it is difficult to realize a high thermal conductivity near the filling limit ϕ f because of the porosity of the composites.

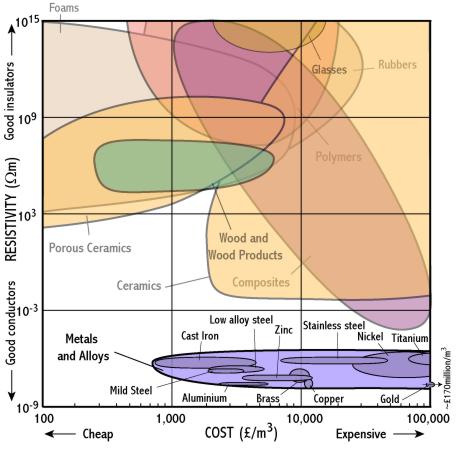

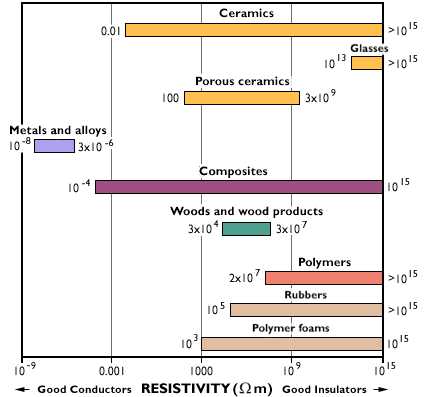

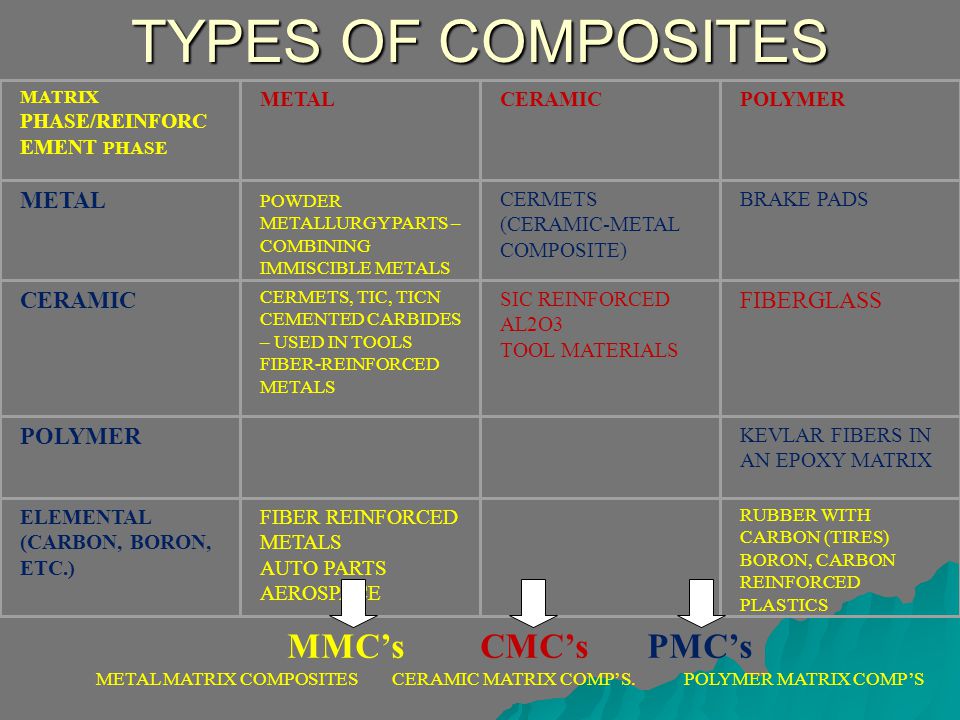

Thermal conductivity of metals ceramics and polymers. As shown in fig. Thus the shape and the spatial distribution of dispersed filler particles are the important factors controlling the electrical and thermal properties of metal filled polymer systems. Tions as seen in their ratio is greater for low thermal conductivity materials like polystyrene and polytetrafluoroethylene than for the higher conductivity materials such as ceramic and glasses. Ceramic fibers in cmcs can have a polycrystalline structure as in conventional ceramics.

The conductivities of composites filled with hard stiff ceramic particles exceeded 3 5 w m k 1 or 20 times the conductivity of the polymer matrix and were shown to be almost independent of the intrinsic filler conductivity range of 33 300 w m k 1. Compare metals polymers and ceramics on a chart or table using the following properties and the ratings low high and highest. A material with a high level of hardness will resist deformation caused by surface indentation or abrasion while a material with a low hardness level will deform more. Thermal conductivity can only be moderately enhanced.

One of the most desired properties of metal alloys is the hardenability. This study describes a new method for the measurement of the thermal conductivity of insulating materials in the range from 0 1 to 1 5 w c 1 m 1 which generally covers polymers ceramics and. Alloying can be applied to metals ceramics and polymers where in each specific properties are desired. Density ductility hardness corrosion resistance hardness thermal conductivity electrical conductivity wear resistance.

1b the thermal conductivity of ceramic polymer composites could also be enhanced to a certain extent by dispersing high loadings up to 70 vol 15 16 17 of ceramic particulate fillers using the polymer molding technique 18 19. There continues to be growing interest in the study of boron nitride bn as a functional filler for polymers due to its extraordinary properties including high thermal conductivity structural stability mechanical properties and anti oxidation ability bn is a refractory chemical compound produced synthetically since it is not found in nature.