Three Advantages Of Monolithic Refactory Ceramics

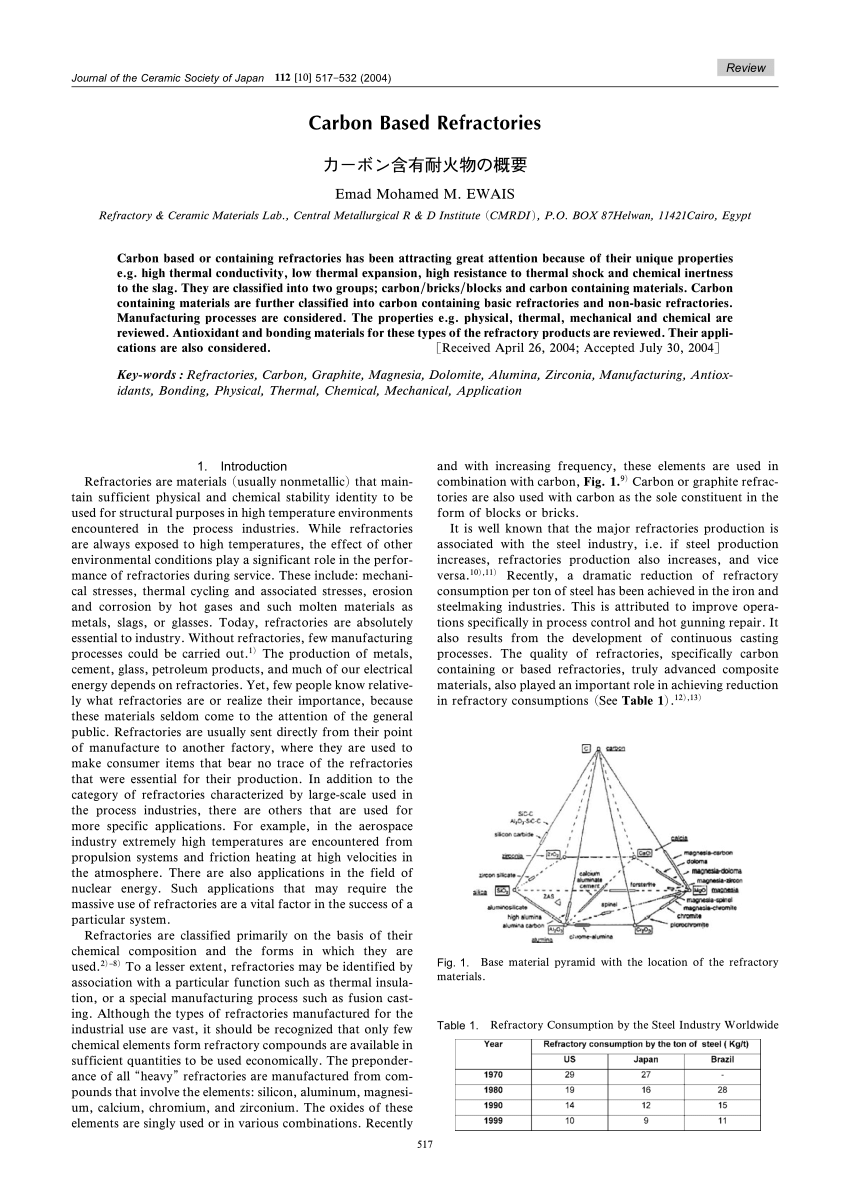

High alumina refractory contains more than 45 al 2 o 3.

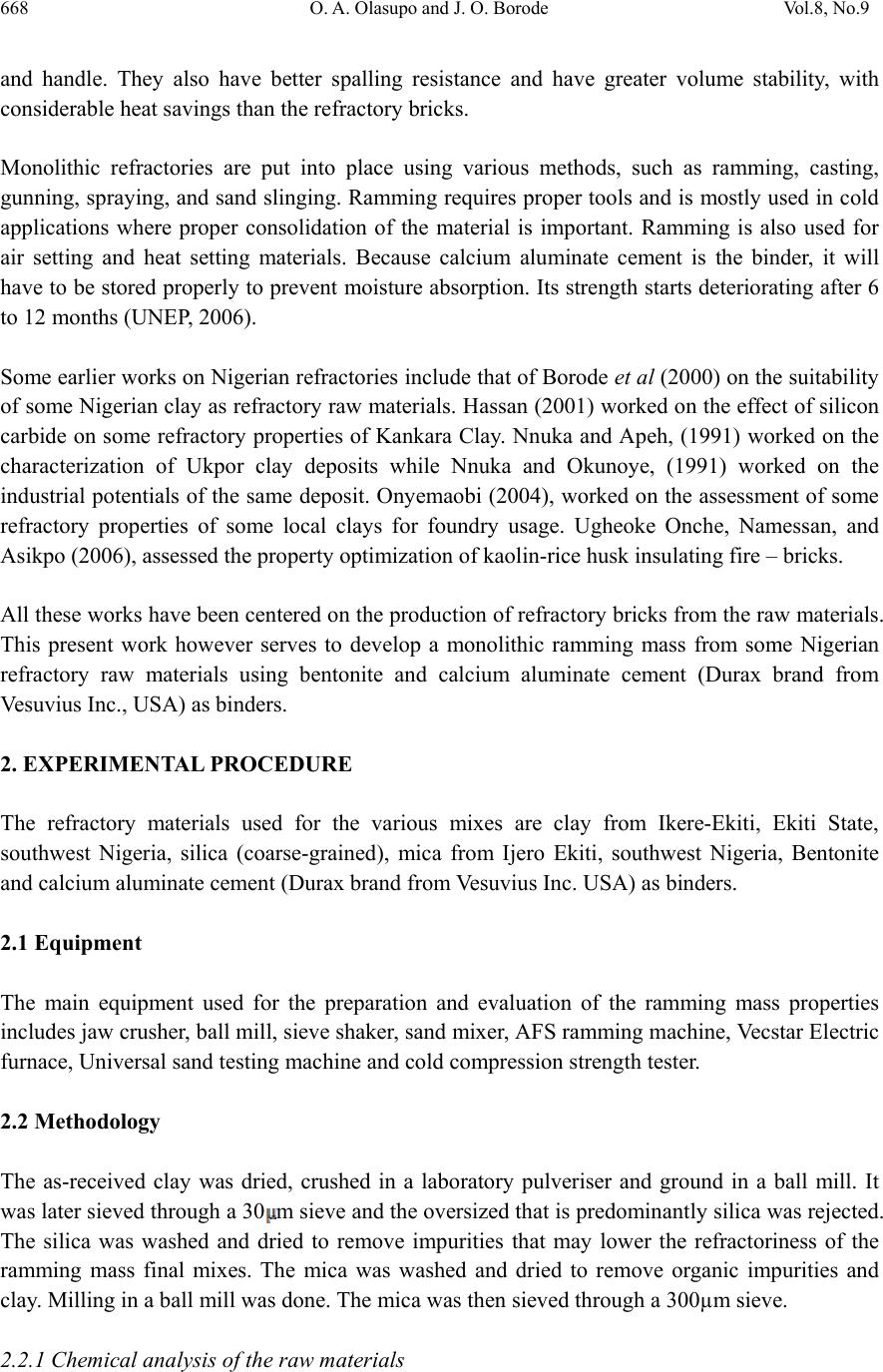

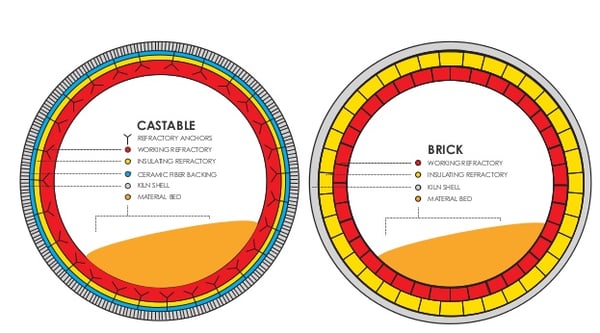

Three advantages of monolithic refactory ceramics. Consistent and controlled manufacturing processes with faster turnaround than traditional cast in place monolithic refractories reduced labor cost over classic brick installations and if well designed simple repair assemblies. Our story why allied we re dedicated to being there for you. Monolithic refractories are special mixes or blends of dry granular or cohesive plastic materials used to form virtually joint free linings. Monolithic refractory makes up a good chunk of that market as much as 40 and rightfully so.

Precast refractory ceramic shapes have had well known benefits over other refractory lining methods. Annual worldwide refractory consumption in the production of cement is estimated to be more than 5 million metric tons or 12 of the total world refractory market and growing. Use of monolithic refractories frequently eliminates difficult brick laying tasks and joints which may be accompanied with weakness in construction. Monolithic refractory castable is dry mixture refractory material.

Monolithic refractory has many different varieties according to their construction type. During the period 1940 1960 major breakthroughs were made in binders with the introduction of intermediate and high purity calcium aluminate cements with cao al2o3 as the principal. Monolithic refractory material has the advantages of simple production. These products have their own characteristics and advantages.

It s faster and easier to install than refractory brick which is why as much as 2 3 million metric tons of monolithic. Monolithic refractory is the name normally given to all unshaped refractory products the word monolithic coming from the word monolith meaning big stone. Ered ceramic matrix composites cmc s in their own right. They have good corrosion and wear resistance and low iron content.

Extremely large aggregates used for improved impact and wear resistance in steel making precast ladle bottoms2 and metallic fibers surrounded by monolithic refractory castable improved fracture toughness3 were both akin to an improve ment of a refractory ceramic matrix composite. Allied offers a variety of engineered ceramic solutions that can be supported globally by our sales and service networks. Their use promotes quick installation avoid delays for the manufacture of special brick shapes. Advanced ceramic custom solutions allied mineral products is a global manufacturer of monolithic and precast refractory ceramics.

They withstand high temperature. Generally speaking the production of monolithic refractory materials is only through the preparation of granules powder materials and the mixing process of the mixture. During the construction the mixture is mixed with liquid which can coagulate and harden after forming for a while thus endowing the material with certain structural strength the monolithic refractory castable can be divided into vibrating castable self flowing. Price of one silica refractory brick is between 0 10 0 70.

Monolithic refractories have advantages over refractory bricks in different type of furnaces.

.jpg)