Transcrystalline Fracture Sem Ceramic

The general factors affecting the fracture toughness of a material are.

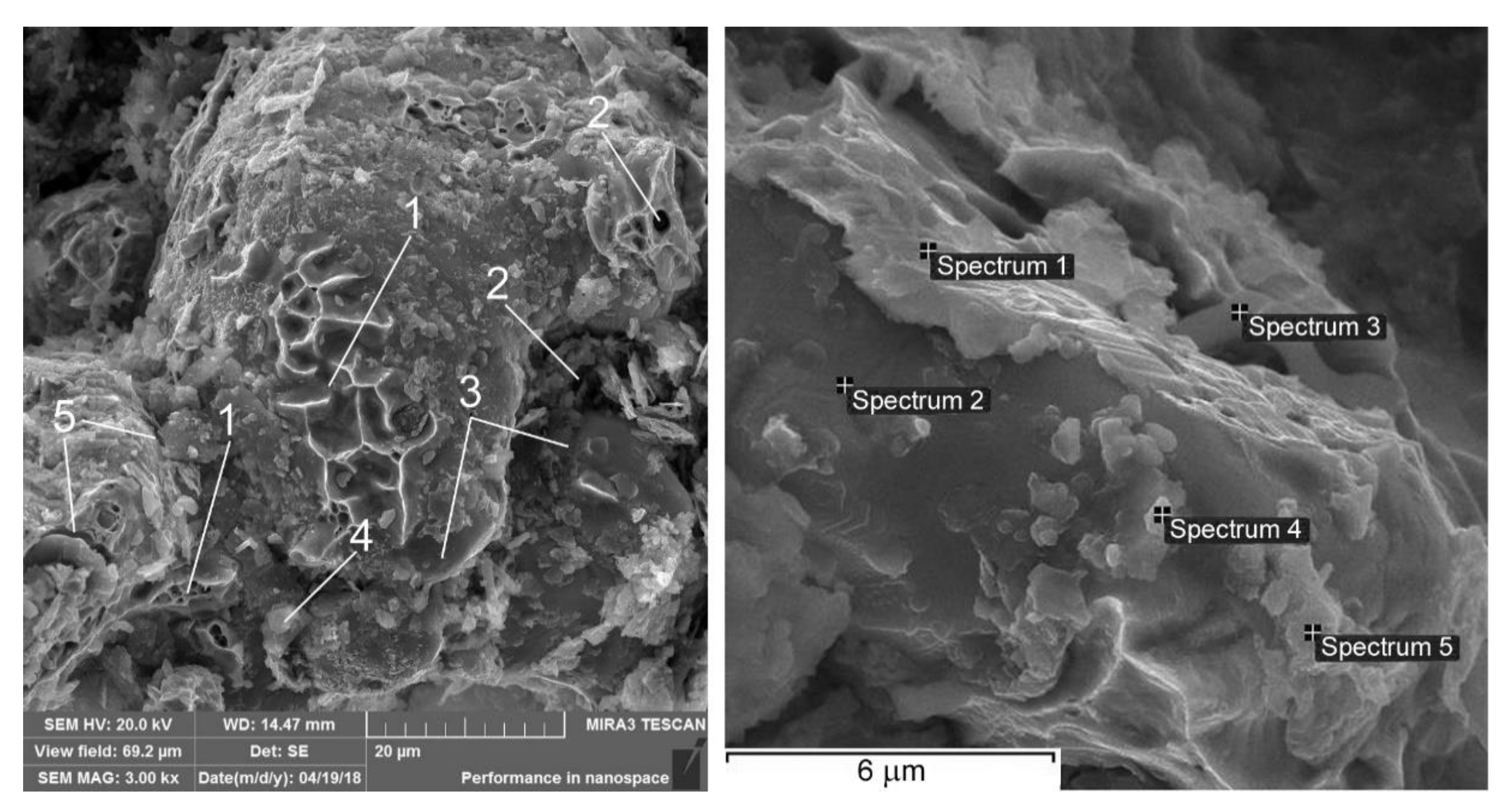

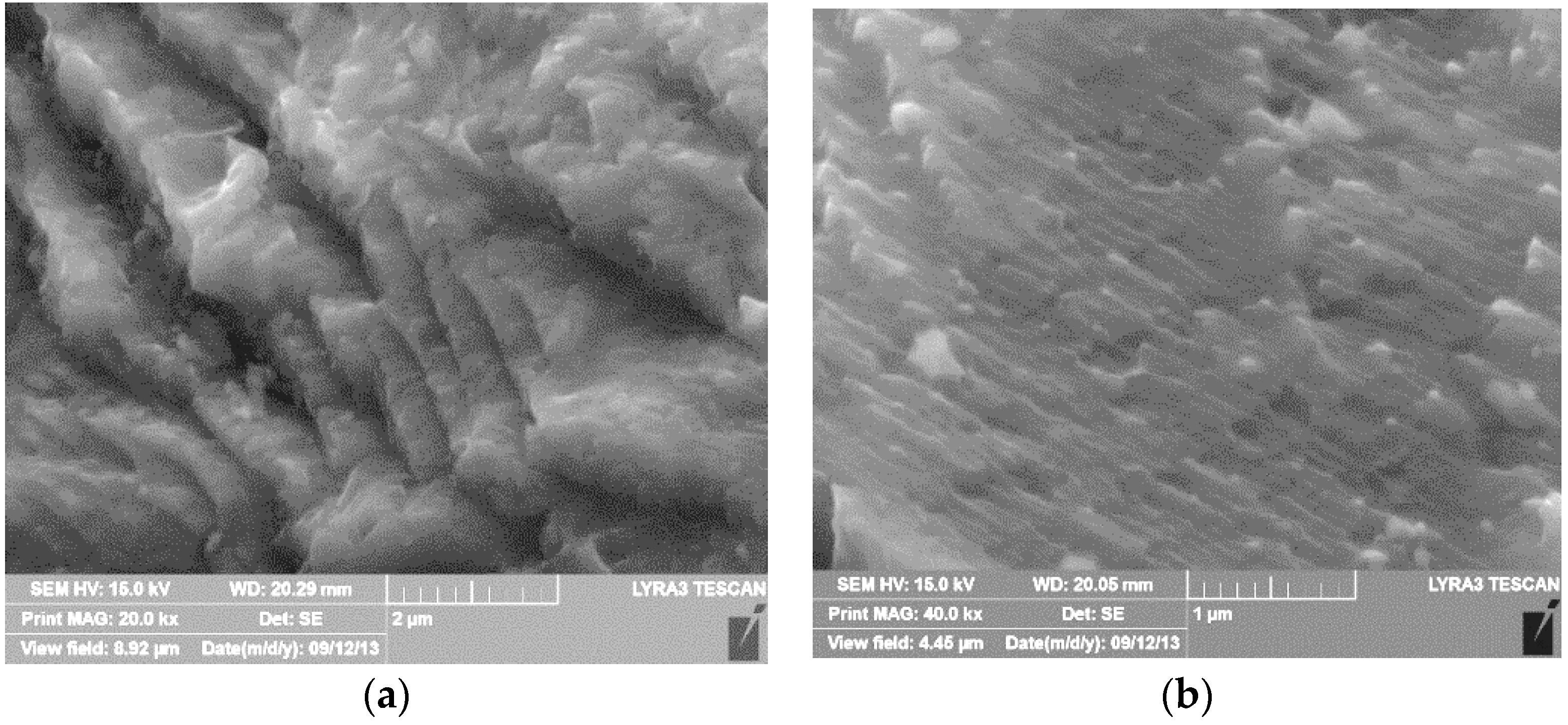

Transcrystalline fracture sem ceramic. But in fig 2 b a transcrystalline fracture among the grains can be observed and this phenomenon. Via the springer book archives and in print. The reasons are due to the higher bonding force in the transcrystalline fracture of coarse grains than that of in the intergranular fracture of fine grains and increasing the propagation path caused by part of intergranular fracture of coarse grains. The similar result was also found in the ceramics.

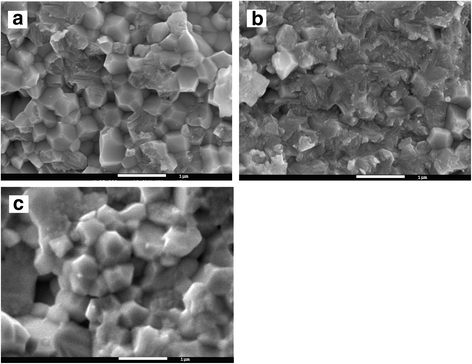

Sem of the surface of a fracture of the w6 1 3 composite. Very little plastic deformation and a shiny fracture surface characterize brittle fractures. A sem procedure for quantifying the percentage area of transgranular fracture and surface roughness was developed to study the fracture morphologies of stable and rapid crack growths in ceramics and ceramic matrix composites. 5 indicates that the milled surface grain size was smaller than that inside the ceramics suggesting that the balls were mainly worn by transcrystalline fracture.

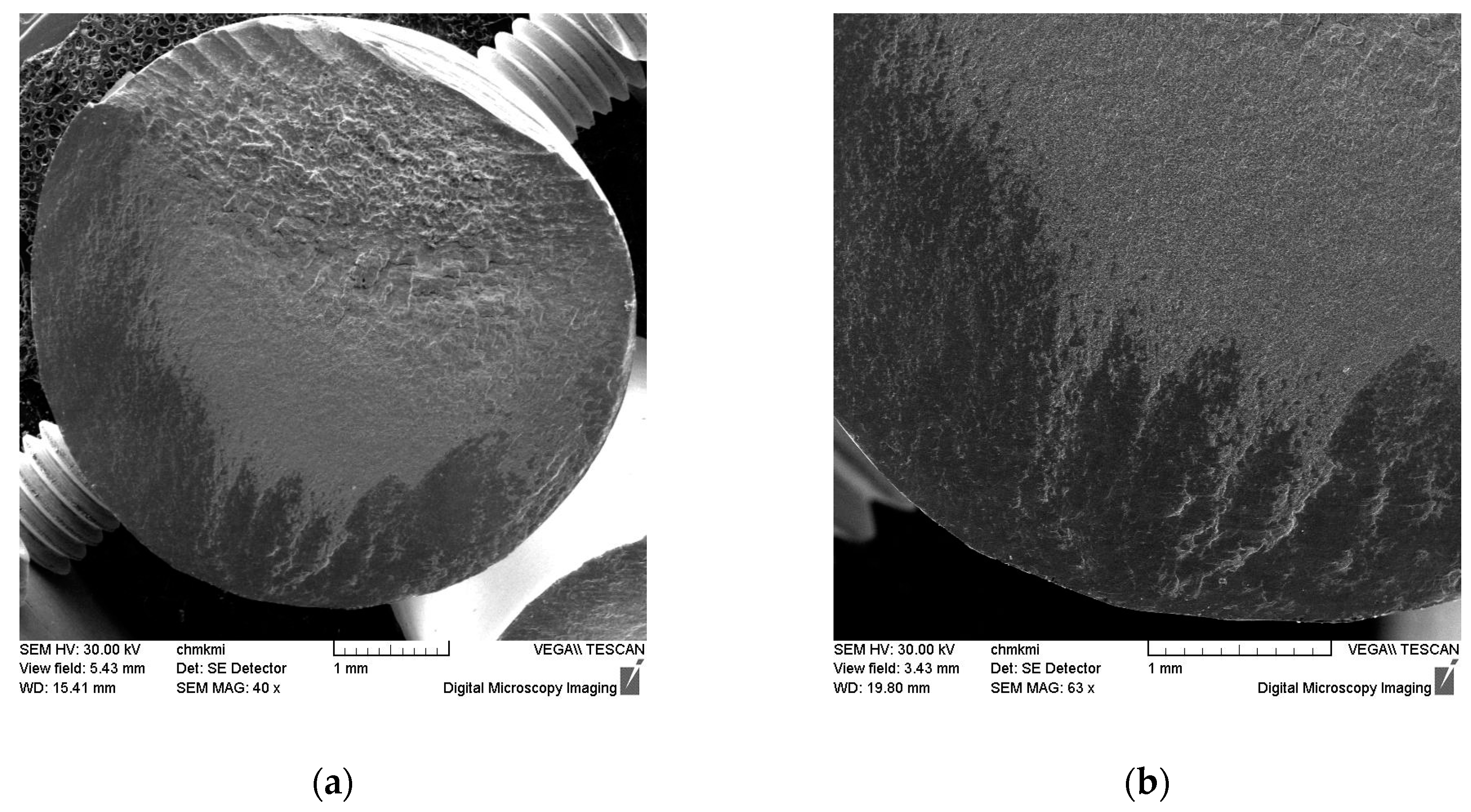

Often chevron patterns point back to the origin of failure 3 figure 3. The prepared ceramic ball surfaces after milling with other balls and ultrasonic cleaning were observed under sem and the results are shown in fig. Sem of the surface of a fracture of the w6 37 44 composite. The procedure utilizes software which interprets the sem line scanning profiles.

Table 3 the mean fracture toughness values and their standard deviation of dental ceramics used in this study materials mean k ic mpa m 1 2 hardness gpa percent crystallization micace35. From the matrix can be seen on the fracture surface while during the fracture most of them break in the transcrystalline manner and remain embedded in the matrix. Examining this type of fracture under the sem the base of the dimples will contain fractured pearlite lamella. Fracture mechanics of ceramics discontinued series although this series no longer publishes new content the published titles listed below may be still available on line e.

Sem micrographs of fracture surfaces of a monolithic n4 8 y o and a si n4 20 vol sic 8 y 0 nano composite courtesy a. It can occur at low stress and propagate with. The fracture toughness was measured by chevron notched beam by single edge pre cracked beam and by the indentation techniques 88 fig. Temperature strain rate presence of structure defects and presence of stress concentration notch on the specimen surface stress intensity factor k is a quantitative parameter of fracture toughness determining a maximum value of.

Structural ceramic nanocomposites 1071 table 3. 10 m 2 5 m 200 m 10 m.