Translucent Arkansas Stone Vs Ceramic

These stones are also relatively hard so the stones rarely require flattening.

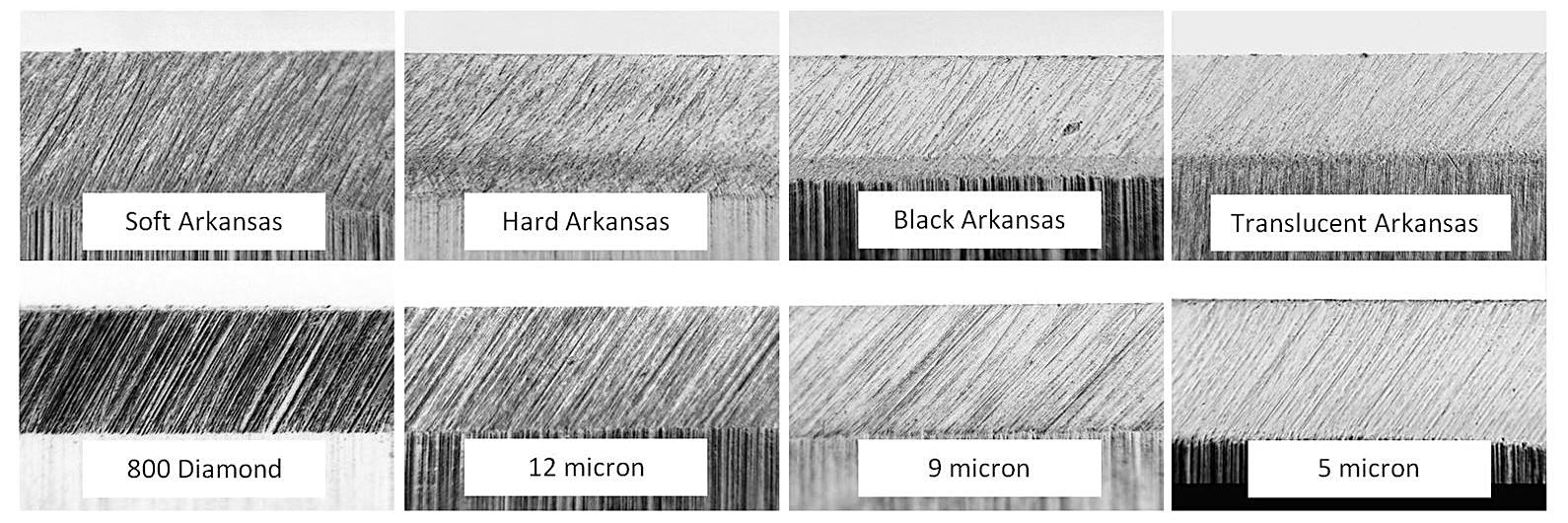

Translucent arkansas stone vs ceramic. Hard translucent arkansas is the top of the line and quite expensive. Grits past this stage provides only modest benefit. There are straight razor users who have put it as high as 8000 grit. Soft arkansas is a medium stone cutting fairly quickly and producing a very sharp edge but not the polished edge hard arkansas produces.

Mirror polish sharpest edge possible extremely slowing. This test puts translucent arkansas equal to 3500 4000 grit. One of the most efficient ways to sharpen. The natural arkansas stones vary in price from the very economical soft arkansas to the more expensive hard black and translucent arkansas stones.

Norton 8000 waterstone dmt extra extra fine diamond stone. The main disadvantage of the oil stone is its slower cutting rate. In contrast to natural novaculite stones aluminum oxide oil stones are a very popular man made choice favored for. The soft arkansas stone removed metal at a much faster rate than expected.

Fast one of the faster ways to sharpen tools depending on stone material. Norton 4000 waterstone hard black arkansas hard translucent arkansas. Norton hard translucent arkansas ultra fine stones are the finest grained and most dense natural stone available and are used to produce the keenest most precision finish possible. These stones can be made out of a myriad of materials.

Leave edge polished to naked eye. Near mirror polish edge is very near perfect. One of the best ways to sharpen multiple tools and lots of them. Natural stone man made stone diamonds embedded on a block alumina ceramic and many other materials.

From practical experience i have always felt the arkansas translucent stone is 4000 grit. The extra ultrafine ceramic is around 70 the ceramics seem attractive because they re actually designed to be used dry and their aluminum oxide ceramic construction should make them cut harder steels better than a. They polish to produce razor like edges.

.jpg)

%2C445%2C291%2C400%2C400%2Carial%2C12%2C4%2C0%2C0%2C5_SCLZZZZZZZ_.jpg)