Types Of Processing Routes For Ceramics

An organic compound which containing of metals and one or more non metals.

Types of processing routes for ceramics. Dry shaping technologies 2. Al2o3 and pottery etc. Potters apply a layer of glaze to the bisqueware leave it to dry then load it in the kiln for its final step glaze firing. Ceramic materials their processing 1.

It is also important to add binders or plasticizers as well. The following are common types of ceramics. Wet shaping or suspension based technologies. This predates the use of metal.

The purpose of ceramics processing to an applied science is the natural result of an increasing ability to refine develop and characterize ceramic materials. Ceramic processing is used to produce commercial products that are very diverse in size shape detail complexity and material composition structure and cost. Modern ceramics include some of the strongest known materials. Ceramic processing minerals chemical processing powder powder processing green body.

Traditionally there are three main technological routes of ceramic shaping. Most often pug mills are the preferred piece of machinery used in this step of the process when dealing with dry mixes. General approaches for producing strong ceramics are to reduce the maximum size of processing flaws or to enhance the fracture toughness. Independent from the intended use ceramic processing starts from an initial powder.

Ceramics an international peer reviewed open access journal. Humans have produced ceramics since at least 24 000 bc. Ceramic glaze is an impervious layer or coating applied to bisqueware to color decorate or waterproof an item. Rosso ceramic andmetal matrix composites.

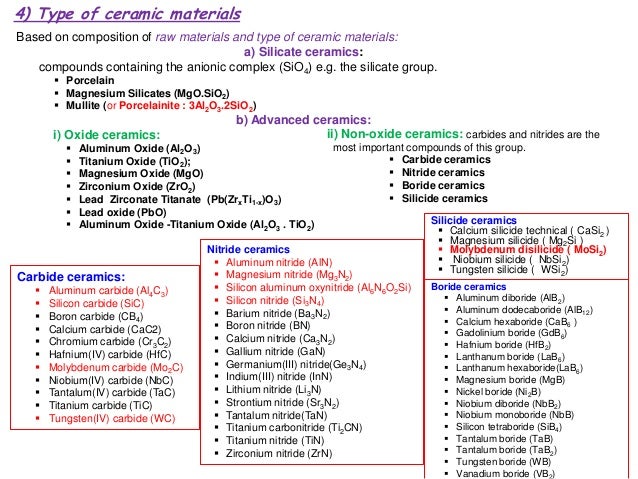

Mixing to obtain a more chemically and physically homogeneous material prior to forming the constituents of the ceramic powder are combined using the method of mixing or blunging. Request pdf processing routes to macroporous ceramics. Types traditional ceramic advance ceramic glasses 2. Brittle types examples of ceramic materials ranging from household to high.

A review macroporous ceramics with pore sizes from 400 nm to 4 mm and porosity within the range 20 97 have been produced for a number. Thermo plastic shaping technologies and. Article processing charges open access policy institutional open access program editorial process awards research and publication ethics. For authors for reviewers for editors for librarians for publishers for societies.

Ceramic materials are in general brittle and according to the fracture mechanics the strength is governed by the flaw size and the fracture toughness. Routes properties journal of materials.