Ultrasonic Machining Dental Ceramics

The surface chippings are evaluated and the subsurface.

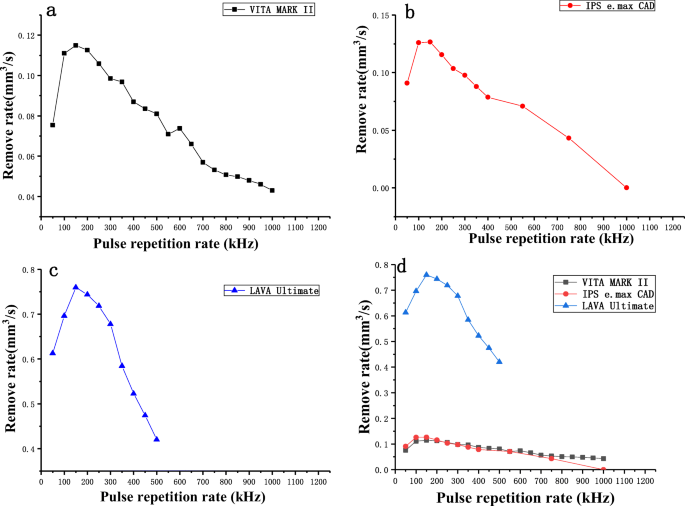

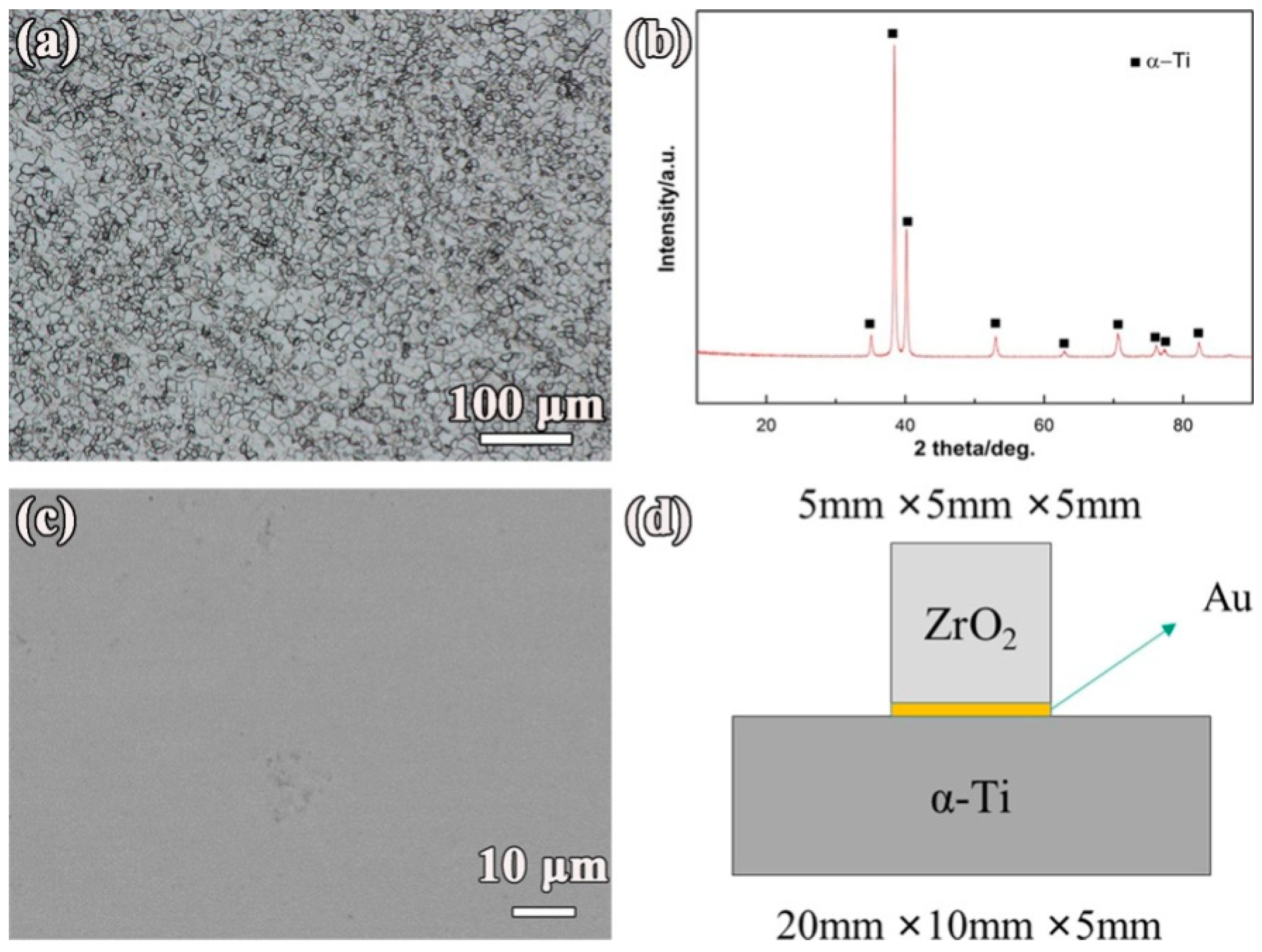

Ultrasonic machining dental ceramics. An experimental study of the rotary ultrasonic drilling of ceramics is first presented. A 25 mm min b 50 mm min c 75 mm min. The influence of different process parameters on the material removal rate for machining of magnesia stabilized zirconia is examined. The interaction effect on surface roughness between cutting speed and ultrasonic frequency when the feed rate is.

Ultrasonic machining new in 2018 ultrasonic technology enables the economical machining of complex workpiece geometries in demanding high tech materials like ceramics glass corundum tungsten carbide or even composites and notably the materion supremex material the kinematic overlapping of the tool rotation with an additional oscillation effects a reduction of the process forces by up to. This paper presents a preliminary study about effects of ultrasonic vibration on machined surface and subsurface damages in rotary ultrasonic machining rum. Kai 17 conducted a study on rotary ultrasonic machining of sintered zirconia dental ceramic and effects of spindle speed on cutting force edge chipping size and subsurface damage were. The surface and subsurface damages are compared for machining of dental ceramics al 2 o 3 with and without ultrasonic vibration.

Then a mechanistic approach to modeling the material removal rate during rotary ultrasonic drilling of ceramics is proposed and applied to predicting the material removal. Machining hard ceramics or soft optical materials has never been faster or easier.